10 to 30 v off voltage.

Light curtain muting standard.

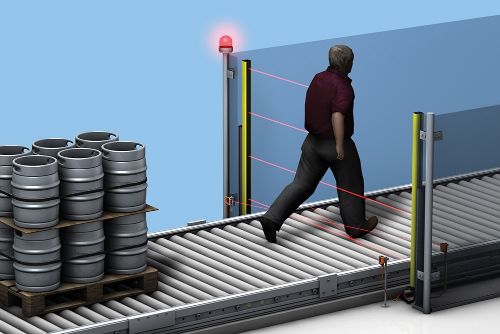

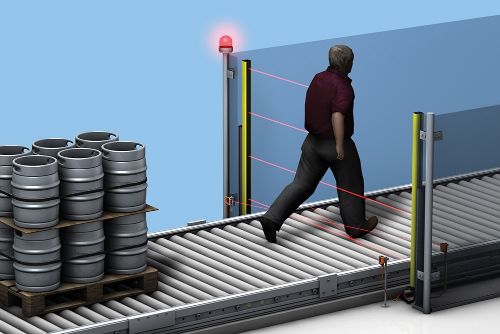

In material handling applications material is allowed to pass through the protective field without shutting down the machine.

Our standard s difficulty here is that 1910 217 c 3 iii d allows muting on the upstroke and this application requires muting during over a much longer portion of the cycle.

At this point the light curtain is muted with the die no more than 1 4 above the workpiece or automatically turned off.

When there is no access for persons but the access for products must be available a muting light curtain offers a perfect solution.

29 cfr 1910 212 states point of operation.

Light curtain with muting two sensor l type and configurable safety relay introduction light curtains are used to detect attempted access to a hazardous area.

Muting light curtain monitoring relays allow the automatic temporary suspension of the safety function if certain conditions are met.

Muting allows the stock to bend and the operator to move through the light plane without stopping the press brake slide.

Muting for most of the stroke is required since the tooling will interrupt the light curtain during normal stroking of the press.

Osha was asked now that the u s.

A safety light curtain shields a hazardous area for people s access.

Also the status output for the mute light changes to green.

When enabled a function block is purple with a 3 second count down timer.

Setup of a muting light curtain.

In normal operation if a light curtain detects an object it causes the safety system to stop any hazardous motion in the hazardous area.

10 to 230 ma can be connected.

From the instant the first of the two muting sensors is cleared.

Incandescent lamp 24 vdc 1 to 5 5 w led lamp load current.

When using a pnp output cable.

Edm input wait input reset input muting input 1 2 override input.

Open or 0 to 3 v short circuit current.

The terms muting and blanking are frequently used incorrectly.

Safety light curtains can be used in a variety of different modes such as muting blanking and floating blanking depending on the needs of the application.

Muting sensors shall be positioned beyond the light curtain in the dangerous area.

This post will help clarify the difference between the two so the correct safety light curtain functionality is chosen and the machine runs safely.

With a muting light screen access to a hazardous area is temporarily disabled muting allowing products to enter the hazardous area.

The timer monitoring the 4 seconds shall be a safety related item.

Muting shall be desabled as soon as the light curtain is cleared and not later than 4 seconds max.

10 ma with edm.

After 3 seconds the status output and mute function turn off.